Aurock has its own characterization devices as well as partnerships with research labs to get some specific properties. In certain cases, the identified properties are inputs needed for numerical simulations.

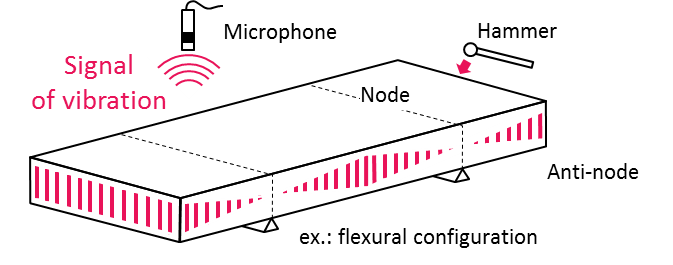

Characterization of elastic properties by acoustic method

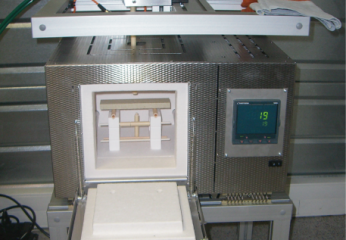

Aurock is equiped with a Resonant Frequency & Damping Analyser (RFDA). The RFDA test rig is used to do impulse excitation measurements from room temperature up to 1050°C under air. The RFDA measures resonant frequencies, internal friction or damping of samples with all kind of materials and allows to calculate the Young’s modulus, Shear modulus and Poisson ratio.

Measurements :

- Young’s modulus (> 1 GPa)

- Poisson’s ratio and Shear modulus

- Damage: comparative material study

- Damping or internal friction

- Defaults detection in metallic materials

- Thermal shocks resistance

- Structural evolution during sintering

- Dectection of phase transformation

- Influence of a coating on the substrate

Sample specificities :

- Homogenous and isotropic

- Bar from 20 to 150 mm long

- Cylinder from 20 to 150 mm long

- Disk from 20 to 100 mm of diameter

Tested materials :

- Ceramics

- Metals

- Glasses

- Polymer

- Refractories

- Concretes

- Other materials…

Measurement according :

- ASTM E 1876, ISO 12680-1, ENV 843-2

- Temperature ranging 20 to 1050°C under air or neutral atmosphere (Argon, Nitrogen)

- Heating and cooling rate : 5°C/ min maximum

- Complex thermal cycles

For non-homogeneous and anisotropic materials or for special geometries, please contact us.

Powder compaction characterization test machine

Aurock has also developed an inorganic powder compaction device in partnership with a laboratory. It allows a quick identification of the parameters of constitutive laws of materials. The parameters can be used for the simulation of the industrial compaction process and therefore to propose process/tooling solutions to improve the final properties, without going through heavy testing campaigns.